Equipment

The research of the Bioenergy & Biofuels LAB is performed by means of lab- and pilot-scale reactors and through analytical equipments.

Lab- and pilot-scale reactors

On one hand, the LAB is equipped with:

- a 15 kg/h reverse downdraft gasifier, for gasification tests at the pilot-scale,

- a continuous lab-scale Hydrothermal liquefaction reactor,

- batch small-scale HTC and HTL reactors,

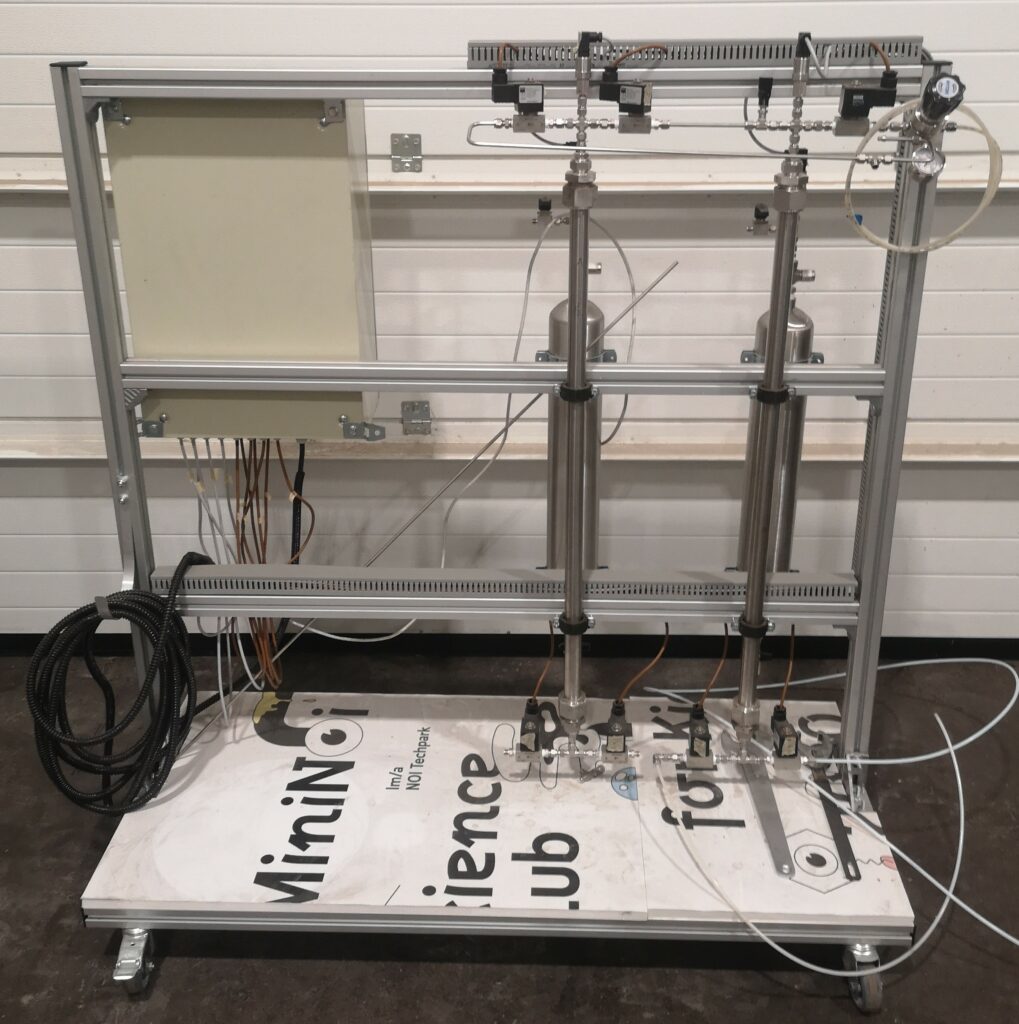

- two 3 liters fermentation units for syngas fermentation and anaerobic digestion testing

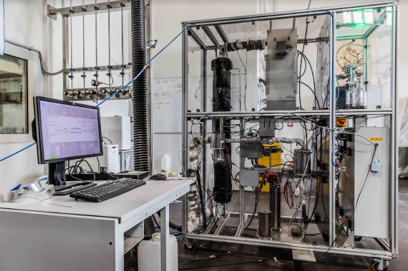

- a catalytic reactor for syngas upgrading & Fischer-Tropsch synthesis,

- batch reactors for testing char filtering and catalytic effects and reactions for pollutants removal,

- a lab-scale PSA system for syngas upgrade and hydrogen separation,

- and other lab-scale apparatus.

Analytical equipment

On the other hand, the LAB is equipped with instruments for the complete characterization of solid and liquid biofuels, such as:

- cutting mill for sample preparation,

- elemental analyzer (CHNS-O with Cl module),

- bomb calorimeter,

- GC-FID for the analysis of liquid samples,

- several apparatus covering a wide spectrum of thermal analysis methodologies (TGA, also coupled with FTIR analysis of the evolved gases, STA, DSC, LFA),

- physisorption analyzer for the measurement of macro and micro-pore size distribution and specific surface area (BET) of solid samples.

The characterization of products and by-products of thermochemical conversion processes is complemented by three gas analyzers (microGC Agilent) and two tar sampling systems according to UNI CEN/TS 15439:2008. These portables apparatus can be used both in the lab and for on-site monitoring campaigns. For this purpose, a power analyzer, an ultrasonic flow meter, a pitot tube and a datalogger equipped with PT100 thermocouples are available, allowing the measuring of all the mass and energy flows within an energy conversion system.